Enhancing Power Supply Infrastructure: Concrete Pole Production Line

In the power supply system, concrete poles play a crucial role. With the rapid development of countries in Southeast Asia, the Middle East, and Africa, the demand for concrete poles is increasing day by day. HAMAC Machinery offers a comprehensive solution for a concrete pole production line to meet this demand.

Brief Overview of the Production Process:

- Prepare high-quality concrete and steel rebar, which should be pre-processed to the correct length to ensure the prestressed characteristics of the pole.

- Place the steel rebar into the concrete pole mold to form a supporting frame.

- Pour concrete into the mold and secure the mold with bolts.

- Place the mold with concrete on a centrifugal machine and spin at high speed to ensure the concrete adheres evenly to the mold walls.

- After removing from the centrifugal machine, place the mold in a steam curing pool to accelerate the curing of the concrete, reaching a 95% curing rate.

- Finally, place the cured pole in the storage area.

Considerations for Investment:

When planning a prestressed concrete pole production line, consider the following factors:

- Purpose of the pole: Power pole or communication pole?

- Design drawings of the concrete pole according to local standards, including the length and diameter of the prestressed pole at both ends.

- The number of poles you want to produce per hour.

- What method will you use to speed up the drying of the concrete, such as a steam curing pool?

Manufacturer's Advantages:

As a leading manufacturer of prestressed concrete pole machines, HAMAC has exported its equipment to many countries, including the Philippines, Indonesia, Malaysia, Uganda, Kenya, Myanmar, and Ethiopia. We provide a full solution for a concrete pole plant and welcome inquiries from those planning to invest in a concrete pole manufacturing plant.

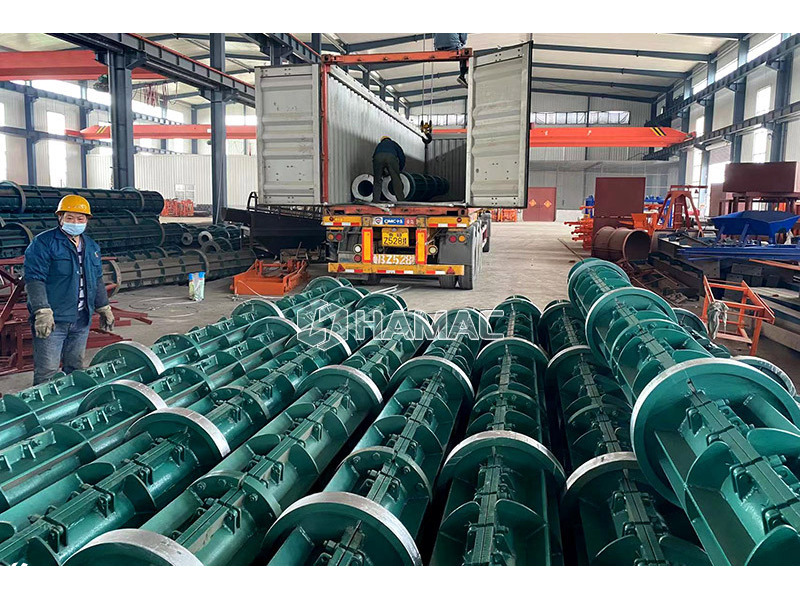

Loading

Loading